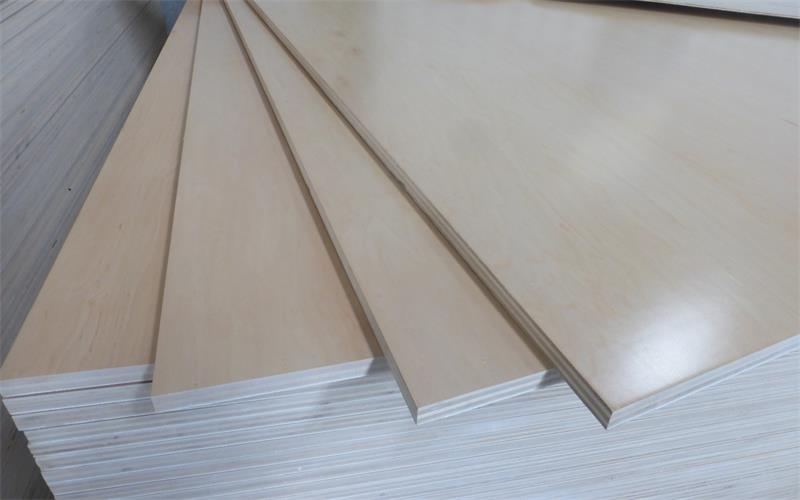

100% Full Birch Plywood: The Ultimate Guide to a Premium Wood Product

100% full-birch plywood is among the highest-quality engineered wood panels available today. Crafted exclusively from birch veneers—without blending lower-grade species—this premium plywood offers unmatched strength, dimensional stability, and aesthetic appeal. Thanks to its cross-grain construction, it resists warping, cracking, and bending, making it the preferred choice for high-precision manufacturing and demanding structural applications.

What Makes Full Birch Plywood Exceptional?

Full birch plywood is built entirely from thin layers of birch veneer, each arranged perpendicular to the previous one. This structure creates a panel that is:

Extremely strong and stable

Highly resistant to deformation

Visually appealing with a clean, tight grain

Reliable for both structural and decorative use

Whether used for fine furniture or heavy-duty construction, full birch plywood delivers consistent, industry-leading performance.

The Meticulous Manufacturing Process

Producing premium full birch plywood requires precise craftsmanship and advanced technology. Every step is carefully controlled to guarantee quality.

1. Log Selection

Only top-grade birch logs with uniform texture, color, and grain are selected to ensure superior appearance and structural integrity.

2. Veneer Production

Logs are peeled or sliced into ultra-thin sheets using advanced rotary lathes or slicing machines. This step determines veneer smoothness and consistency.

3. Drying and Grading

The veneers undergo controlled drying to reach optimal moisture levels. Each sheet is then graded by thickness, density, and visual quality.

High-grade veneers are used for face and back layers, while inner layers maintain strength and uniformity.

4. Gluing & Cross-Layer Layup

Each veneer is coated with a high-strength adhesive. The veneers are stacked in alternating grain directions—this cross-grain orientation is key to the plywood’s exceptional mechanical performance.

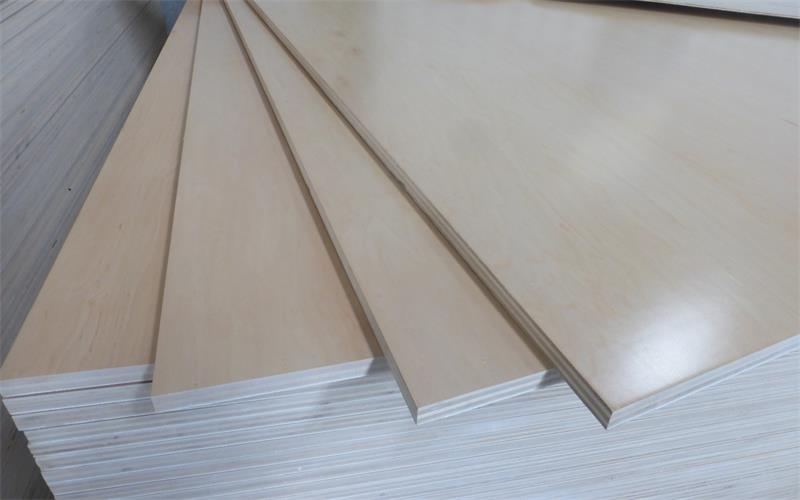

5. Hot Pressing & Final Finishing

The layup is hot-pressed under high pressure and temperature to form a solid, bonded panel. After pressing, the boards are trimmed, sanded, and finished for a smooth, ready-to-use surface.

Applications & Grading Options

Full birch plywood is valued across industries for its strength, clean appearance, and reliability.

Widely Used In:

High-End Furniture: Tables, shelves, wardrobes, chairs

Custom Cabinetry: Kitchen, bathroom, and commercial cabinetry

Home Construction: Flooring, roofing, wall sheathing, subfloors

Decorative Panels: Interior walls, ceilings, partitions

Available Grades (A–D):

A Grade: Clean surface, nearly free of knots—ideal for visible decorative uses

B Grade: Minor natural defects allowed—used for fine furniture and interiors

C & D Grades: For structural or concealed applications

These grading categories allow buyers to choose the most cost-effective panel for their project needs.

Linyi, China: A Global Center for Premium Birch Plywood Production

Linyi has become one of the world’s most important production bases for plywood—especially full birch plywood—offering advantages unmatched by other regions:

1. Reliable Raw Material Supply

A stable flow of birch logs ensures consistent production without shortages.

2. Advanced Manufacturing Technology

Factories in Linyi are equipped with state-of-the-art machinery, enabling precise veneer cutting, efficient drying, and high-pressure pressing.

3. Skilled Workforce

Decades of industry development have created a labor force with deep experience in veneer and plywood production.

4. Cost-Effective Export Pricing

Lower production and logistics costs allow manufacturers to offer globally competitive pricing without compromising quality.

These strengths make Linyi a trusted sourcing hub for importers, wholesalers, and major furniture manufacturers worldwide.

Birch Marine Plywood: Engineered for Extreme Conditions

Birch marine plywood is a specialized variant designed to withstand moisture, outdoor exposure, and demanding environments. Made from 100% birch veneers and bonded with waterproof adhesive, it delivers superior resistance to delamination and structural degradation.

Ideal for:

Boat building

Marine flooring and wall panels

Outdoor decks and furniture

High-moisture construction applications

Its durability far exceeds standard plywood, making it the preferred choice in marine engineering and outdoor architecture.

Conclusion

100% full birch plywood—and its marine-grade counterpart—represents the pinnacle of modern engineered wood. From fine furniture to structural construction, it offers:

For manufacturers, architects, builders, and designers seeking reliability and long-term value, full birch plywood remains an indispensable material.

Contact our team to learn more about specifications, bulk supply availability, and competitive export pricing.