| Availability: | |

|---|---|

| Quantity: | |

7mm,8mm,9mm,10mm, 11mm, 12mm

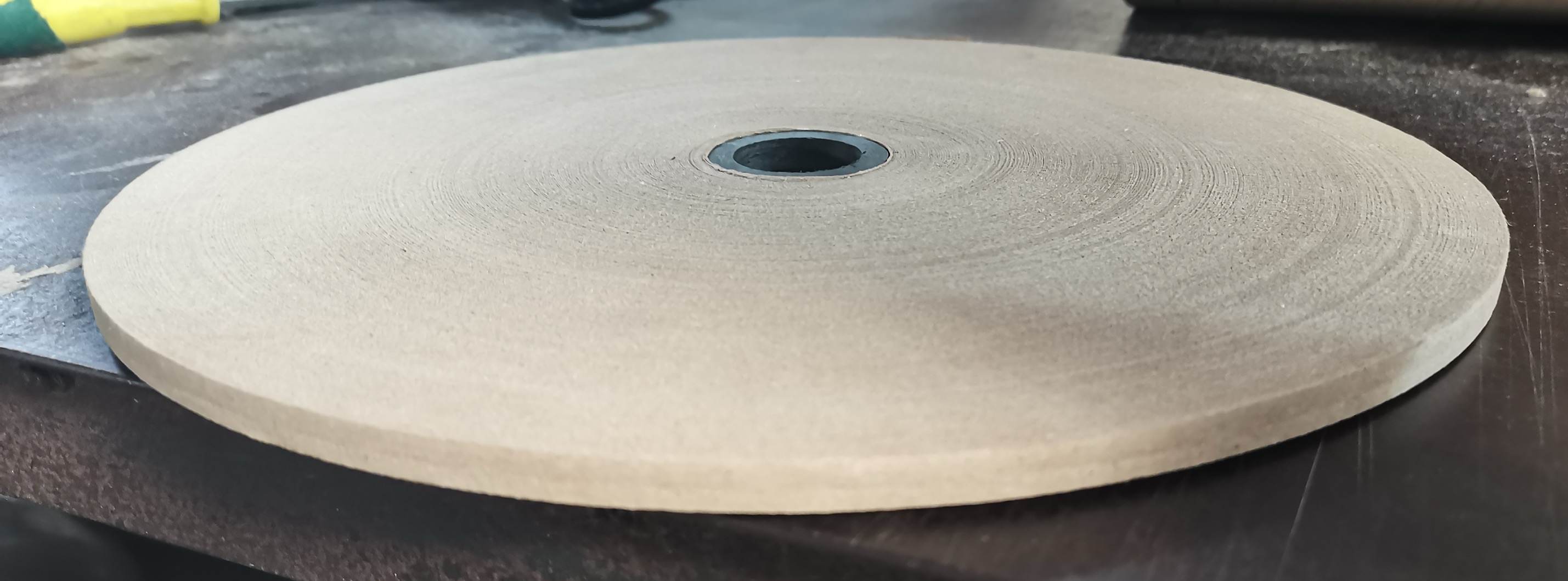

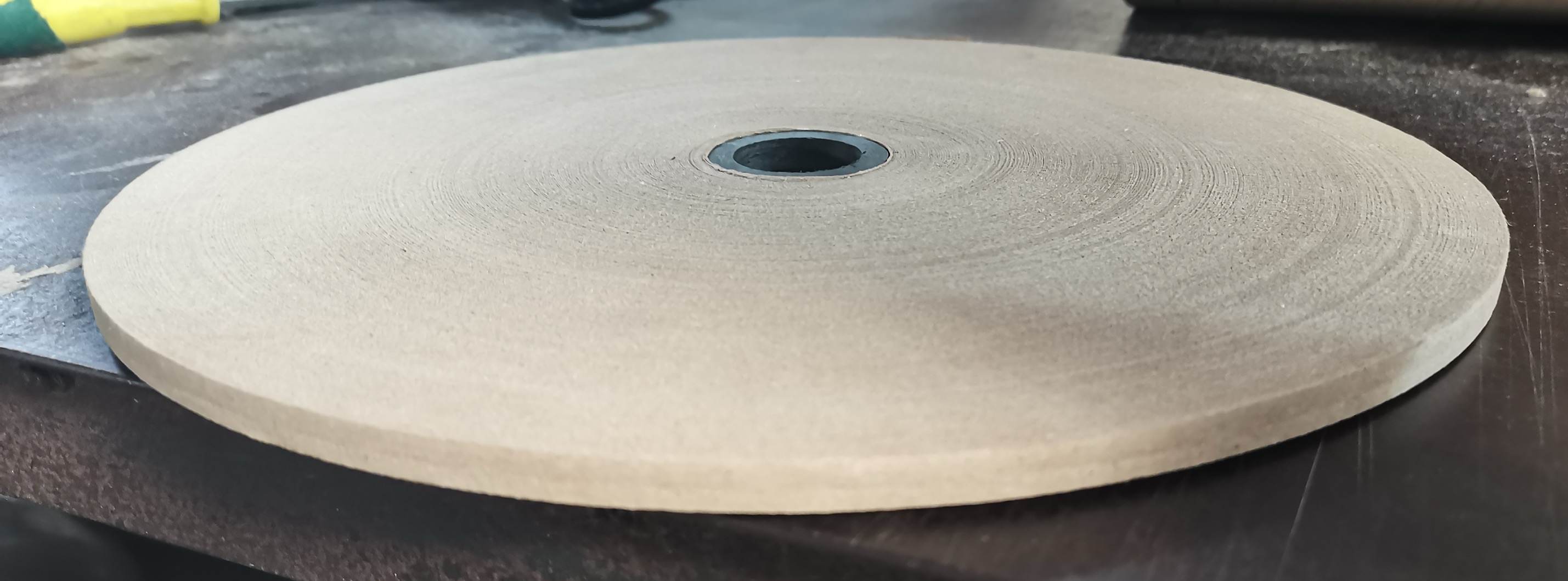

Veneer edge tape is a specialized product designed to seal and protect the edges of thin wood sheets. This tape, often made from water-activated Kraft paper, is a critical component in woodworking for safeguarding veneer from moisture, cracking, and warping. It not only extends the lifespan of wood products but also maintains their aesthetic appeal.

Strong Adhesion: The tape bonds securely to veneer edges, resisting detachment even in various environmental conditions. Its vegetable-based adhesive is activated by water, providing a strong, reliable hold.

Weather Resistance: It is designed to withstand a range of temperatures and moisture levels, making it suitable for diverse applications. The waterproof and non-toxic nature ensures safety and durability.

Seamless Finish: As the tape dries, it shrinks, pulling seams together to create a nearly invisible joint. This ensures a clean, professional finish on plywood, furniture, and other wood products.

Easy to Use: The tape is flexible and simple to apply. It can be easily cut to size and adheres quickly, with any residue sanding off cleanly after the pressing process.

Product Name: Veneer Edge Tape

Materials: Kraft paper with a water-activated, vegetable-based adhesive.

Colors: Available in standard white and brown, with custom colors also possible.

Specifications:

Width: 7mm to 20mm (customizable).

Thickness: 0.09–0.15mm.

Length: 450m–500m per roll.

Features: Strong adhesion, fast tacking, no adhesive residue, non-toxic, and acid-free.

Origin: Linyi, China.

Veneer edge tape is a versatile product used across several industries:

Furniture Manufacturing: It seals the edges of panels to prevent cracking from humidity, enhancing both the durability and appearance of furniture.

Plywood Production: The tape is widely used in plywood splicing to hold veneer sheets in place during the pressing process, ensuring a strong, reliable bond.

Architectural Decoration: It provides a neat and durable edge treatment for decorative wall panels and other interior design elements.

Packaging and Transportation: It protects veneer sheets during shipping, minimizing the risk of damage.

Preparation: Ensure the veneer edges are clean and dry.

Cut & Activate: Cut the tape to the desired length and activate the adhesive with a small amount of water, typically using a damp sponge.

Apply: Firmly press the tape onto the veneer edges, smoothing out any wrinkles.

Press: Use a roller or tool to secure the tape, ensuring a strong bond as it dries.

Finish: After the adhesive has set, the tape can be sanded off cleanly.

For a reliable, high-performance solution that protects your wood projects and delivers a seamless finish, veneer edge tape is the ultimate choice. Its eco-friendly design and excellent performance make it an indispensable tool for professionals in woodworking and manufacturing.

Veneer edge tape is a specialized product designed to seal and protect the edges of thin wood sheets. This tape, often made from water-activated Kraft paper, is a critical component in woodworking for safeguarding veneer from moisture, cracking, and warping. It not only extends the lifespan of wood products but also maintains their aesthetic appeal.

Strong Adhesion: The tape bonds securely to veneer edges, resisting detachment even in various environmental conditions. Its vegetable-based adhesive is activated by water, providing a strong, reliable hold.

Weather Resistance: It is designed to withstand a range of temperatures and moisture levels, making it suitable for diverse applications. The waterproof and non-toxic nature ensures safety and durability.

Seamless Finish: As the tape dries, it shrinks, pulling seams together to create a nearly invisible joint. This ensures a clean, professional finish on plywood, furniture, and other wood products.

Easy to Use: The tape is flexible and simple to apply. It can be easily cut to size and adheres quickly, with any residue sanding off cleanly after the pressing process.

Product Name: Veneer Edge Tape

Materials: Kraft paper with a water-activated, vegetable-based adhesive.

Colors: Available in standard white and brown, with custom colors also possible.

Specifications:

Width: 7mm to 20mm (customizable).

Thickness: 0.09–0.15mm.

Length: 450m–500m per roll.

Features: Strong adhesion, fast tacking, no adhesive residue, non-toxic, and acid-free.

Origin: Linyi, China.

Veneer edge tape is a versatile product used across several industries:

Furniture Manufacturing: It seals the edges of panels to prevent cracking from humidity, enhancing both the durability and appearance of furniture.

Plywood Production: The tape is widely used in plywood splicing to hold veneer sheets in place during the pressing process, ensuring a strong, reliable bond.

Architectural Decoration: It provides a neat and durable edge treatment for decorative wall panels and other interior design elements.

Packaging and Transportation: It protects veneer sheets during shipping, minimizing the risk of damage.

Preparation: Ensure the veneer edges are clean and dry.

Cut & Activate: Cut the tape to the desired length and activate the adhesive with a small amount of water, typically using a damp sponge.

Apply: Firmly press the tape onto the veneer edges, smoothing out any wrinkles.

Press: Use a roller or tool to secure the tape, ensuring a strong bond as it dries.

Finish: After the adhesive has set, the tape can be sanded off cleanly.

For a reliable, high-performance solution that protects your wood projects and delivers a seamless finish, veneer edge tape is the ultimate choice. Its eco-friendly design and excellent performance make it an indispensable tool for professionals in woodworking and manufacturing.