| Availability: | |

|---|---|

| Quantity: | |

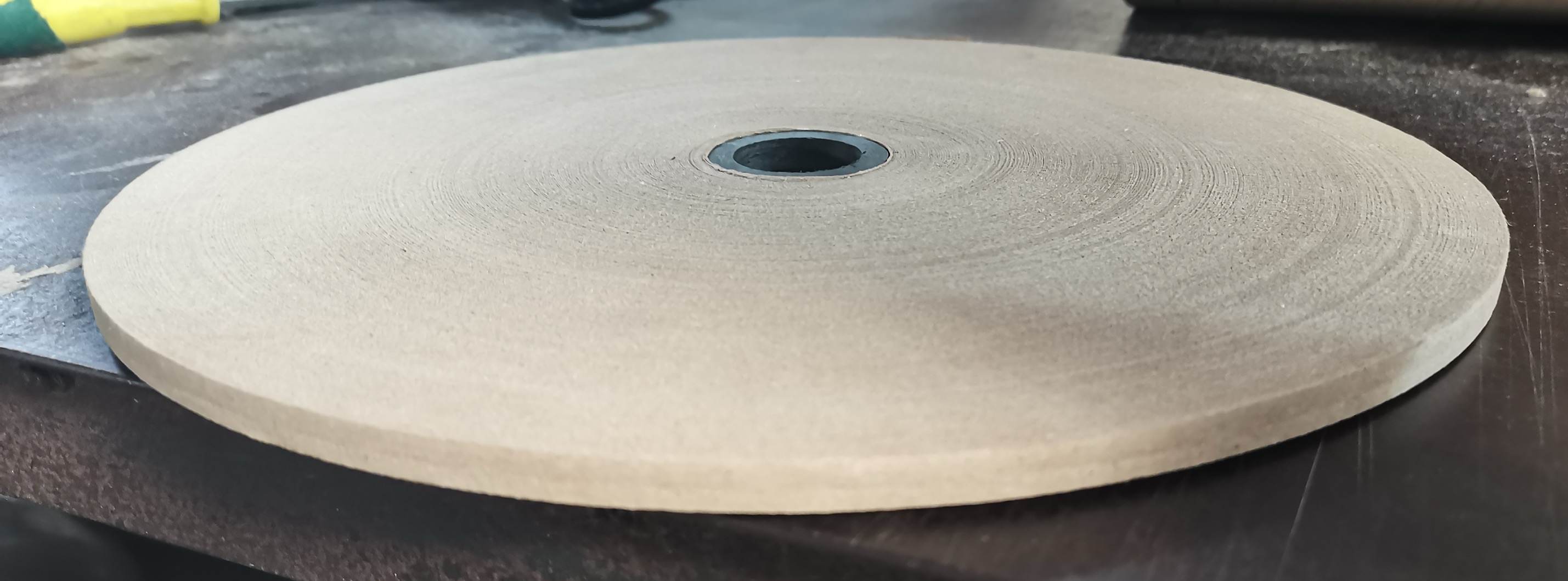

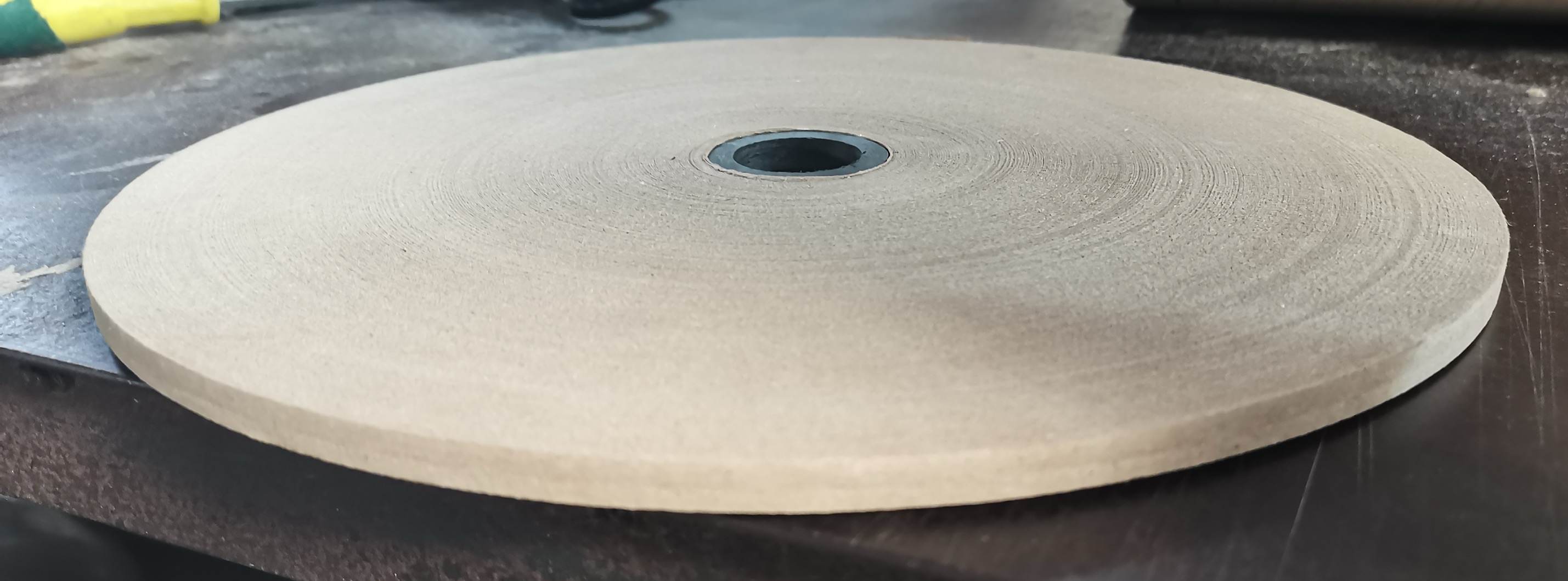

Veneer edge sealing tape—often referred to simply as veneer tape—is an essential material for anyone working with thin wood sheets. Whether you are producing high-end furniture, architectural panels, or decorative veneer components, a reliable edge-sealing solution is critical to protecting your work from moisture, cracking, and wear. This guide explains what makes veneer tape indispensable, where it is used, and how to choose the right specification for your applications.

Modern veneer tape is engineered for performance, efficiency, and ease of use. Kraft-paper veneer tape with water-activated adhesive remains the industry standard, and for good reason:

The tape forms a durable, secure hold along veneer edges. Once dried, it can be cleanly sanded off without leaving any adhesive residue—ideal for refined woodworking and surface finishing.

When moistened, veneer tape shrinks as it dries. This natural tension pulls veneer pieces together, delivering precise joins and nearly invisible seams that elevate the final appearance of your work.

Quality veneer tape resists humidity fluctuations and temperature changes, ensuring your projects remain stable during production, storage, shipping, and long-term use.

Manufactured from non-toxic, non-corrosive kraft paper with water-based adhesive, veneer tape is safe for operators and environmentally responsible.

Veneer edge sealing tape plays a vital role in multiple industries due to its versatility and reliability:

Protects and seals exposed board edges, preventing warping and cracking while enhancing the product’s lifespan and appearance.

Holds veneers securely during fabrication, enabling precise trimming, bonding, and finishing.

Ensures clean edges and durable bonds on decorative panels used in walls, ceilings, and cabinetry.

Ideal for veneer repair, splicing, core patching, and panel assembly—improving structural integrity and overall yield.

Selecting the correct tape ensures professional results and higher production efficiency. Consider the following:

High-humidity environments: Choose waterproof veneer tape.

High-temperature applications: Opt for heat-resistant versions.

Match the dimensions of your veneer. Common widths include 7mm, 8mm, 9mm, and 12mm.

Rotary-cut veneer: Non-perforated tape (8–12mm) helps prevent splitting.

Water-activated glue: Strong, permanent bonding for production processes.

Removable adhesive: Suitable for temporary alignment or lightweight tasks.

Perforated tape: Allows glue to penetrate veneer seams, increasing bond strength.

Non-perforated tape: Ideal for simple edge sealing or general protection.

We supply premium veneer edge sealing tape designed for reliable performance across woodworking and manufacturing environments.

Specifications:

Material: Kraft paper + water-activated adhesive

Colors: White and brown (custom colors available)

Widths: 7mm, 8mm, 9mm, 12mm, and customizable sizes

Length: 450–500 meters per roll

Origin: Linyi, Shandong, China

MOQ: Low minimum order quantity

Lead Time: Fast delivery within 3–7 days

Samples: Free samples available upon request

The right veneer edge sealing tape is a small investment that delivers major benefits—cleaner finishes, stronger edges, and improved efficiency in every project. Avoid costly damage or imperfections by choosing a tape engineered for stability and precision.

Ready to upgrade your production quality?

Contact us today for detailed specifications or to request your free sample. We are here to help you choose the perfect veneer tape for your needs.

Veneer edge sealing tape, also known as veneer tape, is a crucial adhesive tape used to protect and finish the edges of thin wood sheets. It's an indispensable tool in woodworking and veneer processing, helping to prevent moisture absorption, cracking, warping, and physical damage. This guide will walk you through the key features, applications, and how to select the right veneer tape for your projects.

Veneer tape is designed to be both strong and easy to use. The most popular type is made from kraft paper and uses a water-activated glue. Here's why it's so effective:

Strong, Residue-Free Hold: The tape provides a secure bond to veneer edges. After use, it can be easily sanded off without leaving any sticky residue.

Shrinks for a Perfect Seam: When activated with a damp cloth, the tape shrinks as it dries, pulling the veneer pieces together for a tight, nearly invisible seam.

Weather and Durability: It's resistant to moisture and temperature changes, ensuring your wood projects remain protected during transport and long-term use.

Eco-Friendly: Most veneer tapes are non-toxic and non-corrosive, making them a safe choice for both you and the environment.

Veneer edge sealing tape is a versatile product used across various industries, including:

Furniture Manufacturing: Seals board edges to prevent warping and cracking, improving the longevity and look of furniture.

Woodworking: Secures and protects veneer during the crafting process to ensure precision and quality.

Architectural Decoration: Creates a clean, durable finish for decorative panels on walls and ceilings.

Plywood and Panel Production: Used for core repair, splicing, and joining to strengthen and finish wood panels.

To get the best results, consider these factors when selecting your tape:

Material: For projects in humid environments, choose a waterproof tape. For high-temperature applications, a heat-resistant option is best.

Width & Thickness: Match the tape's size to your veneer's dimensions. Common widths range from 7mm to 20mm. For rotary-cut veneer, a non-perforated tape (8-12mm) is ideal for preventing splitting.

Adhesion Type: Water-activated glue is great for a strong, long-lasting bond. If you need a temporary hold, opt for a tape with a removable adhesive.

Perforation: Perforated tape allows glue to penetrate for a stronger bond, while non-perforated tape is better for simpler sealing tasks.

We offer high-quality veneer edge sealing tape with the following details:

Materials: Kraft paper with water-activated glue.

Available Colors: Standard white and brown.

Widths: 7mm, 8mm, 9mm, 12mm, and more (customizable).

Length: 450-500 meters per roll.

Origin: Linyi, Shandong, China.

MOQ: Low minimum order quantity.

Lead Time: Quick delivery in 3–7 days.

Samples: Free samples are available upon request.

Don't let cracked or damaged veneer ruin your projects. Get the best results by using the right veneer edge sealing tape.

Ready to find the perfect veneer tape for your next project? Contact us today for more information or to request a free sample!

Veneer edge sealing tape—often referred to simply as veneer tape—is an essential material for anyone working with thin wood sheets. Whether you are producing high-end furniture, architectural panels, or decorative veneer components, a reliable edge-sealing solution is critical to protecting your work from moisture, cracking, and wear. This guide explains what makes veneer tape indispensable, where it is used, and how to choose the right specification for your applications.

Modern veneer tape is engineered for performance, efficiency, and ease of use. Kraft-paper veneer tape with water-activated adhesive remains the industry standard, and for good reason:

The tape forms a durable, secure hold along veneer edges. Once dried, it can be cleanly sanded off without leaving any adhesive residue—ideal for refined woodworking and surface finishing.

When moistened, veneer tape shrinks as it dries. This natural tension pulls veneer pieces together, delivering precise joins and nearly invisible seams that elevate the final appearance of your work.

Quality veneer tape resists humidity fluctuations and temperature changes, ensuring your projects remain stable during production, storage, shipping, and long-term use.

Manufactured from non-toxic, non-corrosive kraft paper with water-based adhesive, veneer tape is safe for operators and environmentally responsible.

Veneer edge sealing tape plays a vital role in multiple industries due to its versatility and reliability:

Protects and seals exposed board edges, preventing warping and cracking while enhancing the product’s lifespan and appearance.

Holds veneers securely during fabrication, enabling precise trimming, bonding, and finishing.

Ensures clean edges and durable bonds on decorative panels used in walls, ceilings, and cabinetry.

Ideal for veneer repair, splicing, core patching, and panel assembly—improving structural integrity and overall yield.

Selecting the correct tape ensures professional results and higher production efficiency. Consider the following:

High-humidity environments: Choose waterproof veneer tape.

High-temperature applications: Opt for heat-resistant versions.

Match the dimensions of your veneer. Common widths include 7mm, 8mm, 9mm, and 12mm.

Rotary-cut veneer: Non-perforated tape (8–12mm) helps prevent splitting.

Water-activated glue: Strong, permanent bonding for production processes.

Removable adhesive: Suitable for temporary alignment or lightweight tasks.

Perforated tape: Allows glue to penetrate veneer seams, increasing bond strength.

Non-perforated tape: Ideal for simple edge sealing or general protection.

We supply premium veneer edge sealing tape designed for reliable performance across woodworking and manufacturing environments.

Specifications:

Material: Kraft paper + water-activated adhesive

Colors: White and brown (custom colors available)

Widths: 7mm, 8mm, 9mm, 12mm, and customizable sizes

Length: 450–500 meters per roll

Origin: Linyi, Shandong, China

MOQ: Low minimum order quantity

Lead Time: Fast delivery within 3–7 days

Samples: Free samples available upon request

The right veneer edge sealing tape is a small investment that delivers major benefits—cleaner finishes, stronger edges, and improved efficiency in every project. Avoid costly damage or imperfections by choosing a tape engineered for stability and precision.

Ready to upgrade your production quality?

Contact us today for detailed specifications or to request your free sample. We are here to help you choose the perfect veneer tape for your needs.

Veneer edge sealing tape, also known as veneer tape, is a crucial adhesive tape used to protect and finish the edges of thin wood sheets. It's an indispensable tool in woodworking and veneer processing, helping to prevent moisture absorption, cracking, warping, and physical damage. This guide will walk you through the key features, applications, and how to select the right veneer tape for your projects.

Veneer tape is designed to be both strong and easy to use. The most popular type is made from kraft paper and uses a water-activated glue. Here's why it's so effective:

Strong, Residue-Free Hold: The tape provides a secure bond to veneer edges. After use, it can be easily sanded off without leaving any sticky residue.

Shrinks for a Perfect Seam: When activated with a damp cloth, the tape shrinks as it dries, pulling the veneer pieces together for a tight, nearly invisible seam.

Weather and Durability: It's resistant to moisture and temperature changes, ensuring your wood projects remain protected during transport and long-term use.

Eco-Friendly: Most veneer tapes are non-toxic and non-corrosive, making them a safe choice for both you and the environment.

Veneer edge sealing tape is a versatile product used across various industries, including:

Furniture Manufacturing: Seals board edges to prevent warping and cracking, improving the longevity and look of furniture.

Woodworking: Secures and protects veneer during the crafting process to ensure precision and quality.

Architectural Decoration: Creates a clean, durable finish for decorative panels on walls and ceilings.

Plywood and Panel Production: Used for core repair, splicing, and joining to strengthen and finish wood panels.

To get the best results, consider these factors when selecting your tape:

Material: For projects in humid environments, choose a waterproof tape. For high-temperature applications, a heat-resistant option is best.

Width & Thickness: Match the tape's size to your veneer's dimensions. Common widths range from 7mm to 20mm. For rotary-cut veneer, a non-perforated tape (8-12mm) is ideal for preventing splitting.

Adhesion Type: Water-activated glue is great for a strong, long-lasting bond. If you need a temporary hold, opt for a tape with a removable adhesive.

Perforation: Perforated tape allows glue to penetrate for a stronger bond, while non-perforated tape is better for simpler sealing tasks.

We offer high-quality veneer edge sealing tape with the following details:

Materials: Kraft paper with water-activated glue.

Available Colors: Standard white and brown.

Widths: 7mm, 8mm, 9mm, 12mm, and more (customizable).

Length: 450-500 meters per roll.

Origin: Linyi, Shandong, China.

MOQ: Low minimum order quantity.

Lead Time: Quick delivery in 3–7 days.

Samples: Free samples are available upon request.

Don't let cracked or damaged veneer ruin your projects. Get the best results by using the right veneer edge sealing tape.

Ready to find the perfect veneer tape for your next project? Contact us today for more information or to request a free sample!